Advantage Laser Installs 21.8KW Solyndra Solar Array

Next week we begin installation of rooftop solar array on our MICR

toner cartridge manufacturing facility in Atlanta, Georgia. The

solar project has been broken into three arrays. We will start by

installing Array #1 - a 21.8KW array that will produce 29,654 KW

hours per year. This will only provide about 23% of the power we

currently use. Once Arrays #2 and #3 are built the complete system

will provide 70% of our power usage. Our goal will be to become

power neutral meaning we produce 100% of the power we need. So after

all 3 arrays are installed, we will have to decrease our power usage

by 30% via increased efficiency e.g. LED lighting project (more on

that later).

It

Makes Environmental and Business Sense

The environmental benefits of solar power are obvious, the challenge

is to operate as green as possible and still remain a viable

business. I looked at solar a couple of years ago, but it was

difficult to make the numbers work. The federal government was

giving a 30% tax credit and the state (Georgia) had no incentive

whatsoever. Several months ago Mark Bell with

Empower contacted us about

solar. He got us up to date on solar power legislation and

incentives. Solar (green) power was included in the economic

stimulus and recovery act of 2009. Now the federal government will

pay the 30% as a grant up front and the state of Georgia will give

an additional 35% tax credit towards a commercial solar

installation. This made all the difference. The federal grant, means

we don't have to borrow as much money. The state also has a grant,

but it is limited to $2.5 million and applications flooded the GEFA

office. The rebate program was closed after just one day. So we're

going the tax credit route, which creates a challenge in itself.

Sometimes I think the tax aspects of a solar array are much more

complex than the technical ones. After calls to two accountants, the

state and Empower, we determined the array would pay for itself in

about five and a half years. Not bad, after that we'll have an array

with a 25 year life expectancy with free green power.

Solar

Panels Made in the USA

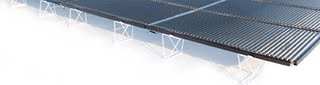

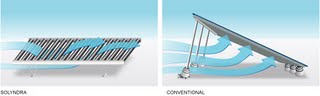

Much of the solar PV (PhotoVoltaic) is dominated by China these

days. We prefer to buy products made here in the USA when we can.

Lucky for us, we have a white roof. Why should this matter? This

allowed us to install a new innovative solar panel from Solyndra

(made in Silicon Valley CA). Traditional PV uses a solid panel that

is angled to the sun to maximize efficiency. But angled panel makes

a great sail and therefore it requires a physical attachment and

penetration through the roofing system or a heavy ballasting system.

Solyndra has a revolutionary solar panel that uses a series of tubes

with space between them so that the wind passes right through them.

The tubes on the Solyndra panel absorb the sunlight that is

reflected off the white roof as well. The result is an array that

can be installed in a fraction of the time and maximizes efficiency

per square foot. The Solyndra panel costs about twice as much as a

traditional panel, but the savings in installation time and mounting

brackets make them come out about even. We are one of the first

Solyndra customers in the Southeast for a technology that may

revolutionize solar installations on many flat-roofed buildings.

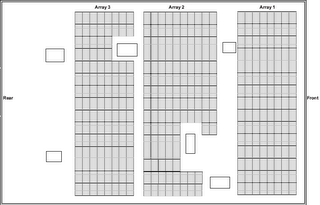

Below is our rooftop layout of all 3 arrays. Array #1, on the far

right, will be the first. Installation of all three was too much of

a financial burden. Our goal is to install an array each year for

the next 3 years.

Once Arrays 2 & 3 are complete, our system power will be a total

of 65.9 KW producing 85,865 KW hours a year.

Another option we have is to sell our "green" power to GA power through their Green energy buyback program. In this program, we take 100% of our green power and sell it to GA Power for $0.18 per KWH (about 4-5 cents per KWH than we pay for solar power). Right now GA Power's green energy buyback is closed to new energy providers. The program is capped 1.5 Megawatts per year, which isn't that much.

Increasing Efficiency

We are also replacing the largest two of our four HVAC units with new Trane High Efficiency units. We've also added rooftop motion detection and surveillance cameras. This will double to protect our solar array as well as our HVAC units from copper theft.

Installing a solar array has some exciting possibilities, but before you take the plunge, do the research. There is a lot to learn, especially about the tax code and what you can deduct and what you can't. But in the end, if you have a long term perspective, investing in a solar array makes sense. Imagine the energy savings and decrease in air pollution that would be possible if every business with a roof filled them with solar panels.

Day

1 of the solar panel project got off to a bad start. The crane started

setting up at 9:00 and was ready to go, but we had no panels. The truck

was already a day late and communication with the trucking company was

terrible. First the panels were supposed to be there Monday morning,

then Monday evening, then Tuesday morning at 7:00 sharp, then at 9:00

they were an hour out, finally the panels arrived at 2:00pm Tuesday.

Meanwhile we had 10 people standing around with little to do.

Day

1 of the solar panel project got off to a bad start. The crane started

setting up at 9:00 and was ready to go, but we had no panels. The truck

was already a day late and communication with the trucking company was

terrible. First the panels were supposed to be there Monday morning,

then Monday evening, then Tuesday morning at 7:00 sharp, then at 9:00

they were an hour out, finally the panels arrived at 2:00pm Tuesday.

Meanwhile we had 10 people standing around with little to do.

Once

the panels arrived, we got to work with the crane. We had 8 pallets of

panels and two more pallets of support legs and other misc hardware. The

nice thing about the Solyndra panels is they are so fast to install.

Once we got trained on the assembly, we were able to have all 125 panels

installed by 6:30 that evening. Yes, we did finish in the dark, but it

felt good to get the panels installed.

Once

the panels arrived, we got to work with the crane. We had 8 pallets of

panels and two more pallets of support legs and other misc hardware. The

nice thing about the Solyndra panels is they are so fast to install.

Once we got trained on the assembly, we were able to have all 125 panels

installed by 6:30 that evening. Yes, we did finish in the dark, but it

felt good to get the panels installed.

Check out more photo's of the solar array.

Thursday, January 21, 2010

Selling Green Power vs. Decreasing Peak Load

As we harvest energy from the sun there are several ways to

take advantage of it. One is to use the power ourselves with

net metering. With net metering our meter "run backwards"

when we're producing more energy than we're using. Otherwise

it just slows down our meter. An advantage of net metering

is we can use the solar array to decrease our peak load.

Commercial customers are charged per KWH, but GA Power has

incentives to business to smooth out their power usages by

charging more, the higher your peak load. Each month a

commercial business peak load rate is determined by the

highest half hour power usage in the previous 11 months. The

business about calculating peak load appears to be

intentionally designed to be confusing. Empower has been

working with us to see if they can decrease our peak load,

and thus lower our overall price we pay per KWH.

Another option we have is to sell our "green" power to GA power through their Green energy buyback program. In this program, we take 100% of our green power and sell it to GA Power for $0.18 per KWH (about 4-5 cents per KWH than we pay for solar power). Right now GA Power's green energy buyback is closed to new energy providers. The program is capped 1.5 Megawatts per year, which isn't that much.

Increasing Efficiency

We are investigating a LED lighting project that would

replace all of our existing florescent lights with new LED

fixtures. Initial estimates indicate we would save about

15KW with the LED project. Empower is also consulting with

us on the LED lighting project as well.

We are also replacing the largest two of our four HVAC units with new Trane High Efficiency units. We've also added rooftop motion detection and surveillance cameras. This will double to protect our solar array as well as our HVAC units from copper theft.

Installing a solar array has some exciting possibilities, but before you take the plunge, do the research. There is a lot to learn, especially about the tax code and what you can deduct and what you can't. But in the end, if you have a long term perspective, investing in a solar array makes sense. Imagine the energy savings and decrease in air pollution that would be possible if every business with a roof filled them with solar panels.

Wednesday, January 20, 2010

Advantage Laser Solar Panel Project - Day 1

Check out more photo's of the solar array.

Solar Panel Project - Day 2

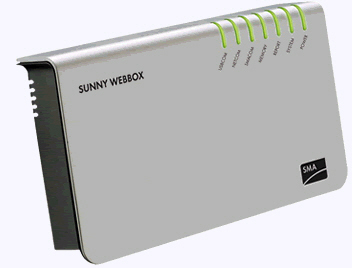

While

we were on the roof, the electrician ran conduit from the roof

penetration to the inverters (indoors). 3 SMA SunnyBoy inverters will do

the job, but they take up way more wall space than I'd hoped. I have no

idea where we will mount the inverters for future arrays. We went with

three inverters to save money over buying one large inverter, but there

is a space penalty.

Day 3 is a bit of a wash, as it's raining, so nothing will happen on the

roof. The electricians will be able connect the inverters to our panel.

This is how the power gets into our system. We also wired the sunny boy

webbox to the inverters which will enable us to monitor real time power

production and see exactly how much power is generated by the system via

a web browser.

Day 4 - assuming it's sunny, we should be able to run the power from the

splicer box to the inverters and crank it up. That's the plan.

Tuesday, January 26, 2010

Solar Project

- Day 7

It's been a week and we are now producing solar power, real

green power delivered free from the sun! The array was installed

in one day. It took another 2-3 days for the electricians to

mount the inverters and run the conduit from the array to the

inverters to our panel. Yesterday was sunny, so it was a good

day to crank up the inverters and see what we were producing. We

could have started it sooner, but it was rainy on Friday and the

engineers from Empower didn't want to launch on a cloudy day

because there was still more testing to go and they wanted to

see the array perform at full power. We're producing 11KW of

power right now at 11:20. That's actual power delivered into

our electrical system after any loses from the inverter.We

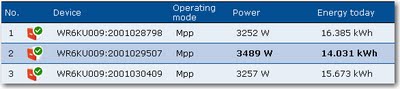

actually have three 6KW inverters. Here's some actual data from

each inverter...

The SMA WebBox collects data from the inverters on power

generated and CO2 emissions avoided. You can checkout our power

production at anytime from our

SunnyPortal.

Right now it doesn't show much power generated, but it will.

The system isn't real time and only gets updated every so often.

Still it's nice to be able to monitor the power generated by the

system.

The SMA WebBox collects data from the inverters on power

generated and CO2 emissions avoided. You can checkout our power

production at anytime from our

SunnyPortal.

Right now it doesn't show much power generated, but it will.

The system isn't real time and only gets updated every so often.

Still it's nice to be able to monitor the power generated by the

system.

At this point there really isn't much to do with the system. PV

systems such as this are relatively maintenance free. Annual

maintenance includes pressure washing the panels and the roof

underneath the panels, as the Solyndra modules rely on the

reflective surface of the white roof for 20% of their power

generation. I'll update in the future on the system performance

promised vs. delivered. -Marvin